Roller chains Drive chains Conveyor chains Attachment chains Leaf chains Welded chains Cast iron chains Chains for water treatment systems Sprockets for conveyer chains Sprockets for roller chains Chain tensioners Elevator buckets Vibrating conveyors Accessories

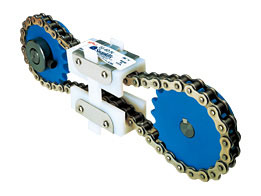

Snapidle™'s patented concept induces minimal wear to the chain drive since the chain rides on the side plates. (U.S. Patent No:4,662,862 - 4,798,562. Foreign Patents Pending) Snapidle™ provides a constant amount of tension to the chain drive, increasing drive life. It tensions, guides, quiets, controls and increases both chain and sprocket life. It requires no mounting devices or maintenance and is a benefit to the drive system, not a deterrent. Economical, easy to install, maintenance free, the Snapidle™ is the answer to the problem of controlling drive chains. By being able to take up tension through the chain, Snapidle™ eliminates the need for adjustable center distance drives. All chains may be ordered in even pitches (eliminating half links) since the additional tension may be taken up by the Snapidle™. Since the Snapidle™ "floats" on the chain drive and actually absorbs shock, it does not add to vibration in the drive. Both sprockets will have the maximum chain wrap possible, thereby increasing chain life (load sharing) and sprocket life (the chain is unable to crawl out of the teeth). On large chain drives, the expense required to install a tensiong system may be unrealistic. A Snapidle™ unit at a fraction of the cost of traditional tensioning methods can tension almost any roller chain drive. Many multiple strand drives cannot be tensioned by traditional idling or tensiong systems, but are readily fitted with Snapidle™ economically.